← Datenschutzerklärung Muster Englisch Dauervollmacht Kita Muster Bullet Journal Vorlage Pdf →

This approach originated in japan at toyota motor company.

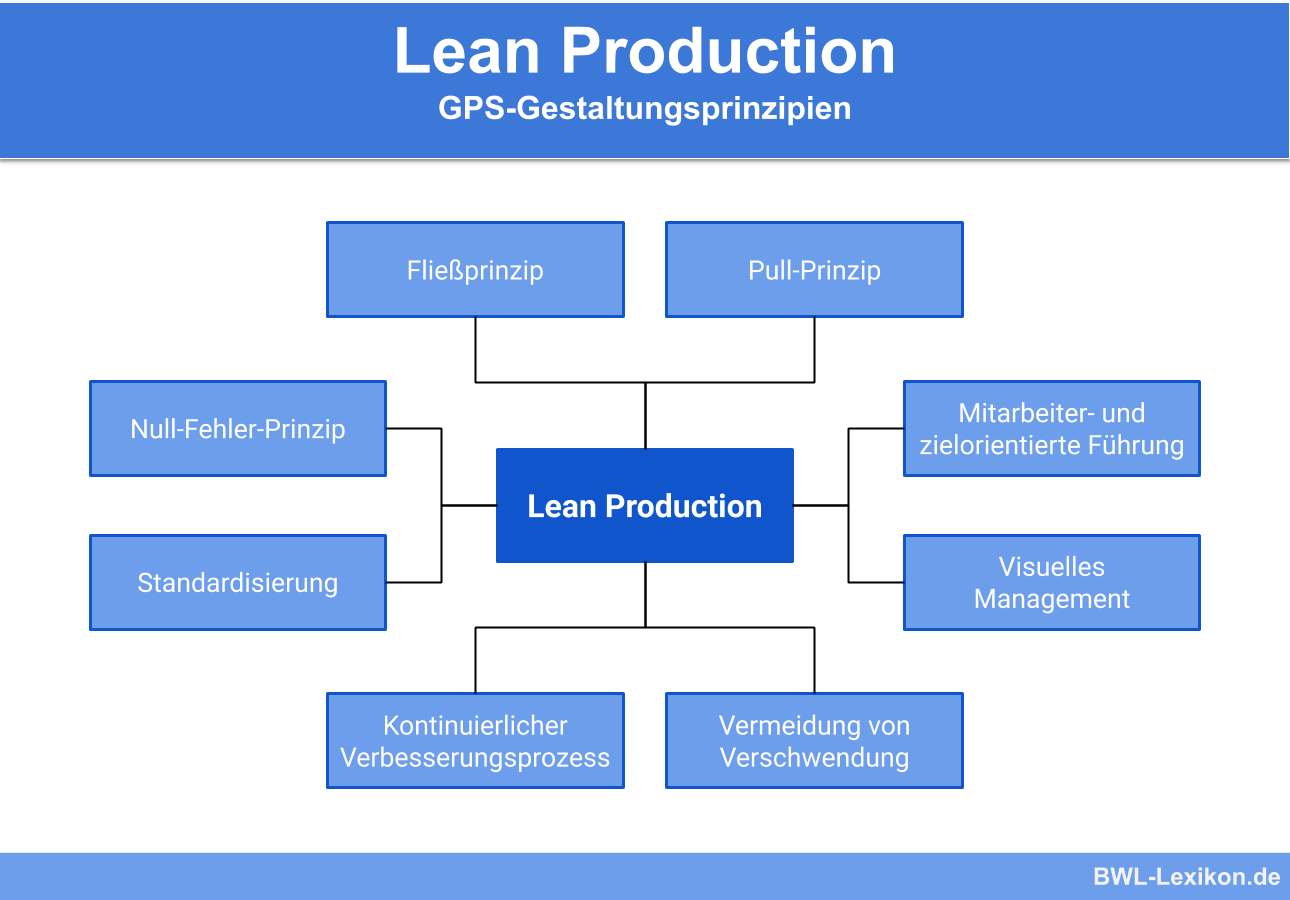

Lean production beispiel. Lean is a suite of four complementary interconnected principles each geared towards increasing value to the customer by improving efficiency. It is striving for interruption free processes. It is the systematic elimination of waste.

The toyota production system or lean management has been described in many ways. Lean production am beispiel toyota grundlage für die heutige lean production war das toyota produktionssystem auch tps genannt. Learn more about the benefits of lean in our ebook tips for implementing lean manufacturing practices.

He probably realized this is the right way to generate value for the customer. It is many things. Put simply lean thinking or toyota way トヨタウェイ is delivering value from the customer s perspective and eliminating waste or muda 無駄.

It is continuous improvement. Click the button below to access your free copy. A manufacturer that implements lean manufacturing is making a commitment to bettering itself through more efficient processes which can only lead to further delighting customers.

Der damalige vorsitzende der toyota motor cooperation sah sich aufgrund von sparmaßnahmen einer isolationspolitk und einer bestehenden knappheit an rohstoffen gezwungen zu einer just in time produktion überzugehen. Taiichi ohno who is considered the main architect of the toyota production system devoted his career to eliminating waste muda from production processes. As a result many manufacturers have deployed extensive process review and analysis programs to move towards a higher level of lean manufacturing.

Lean six sigma project increases production by 58 and lowers energy costs by 263k for british aerospace supplier featuring james yates. Lean manufacturing also known as lean production or simply lean is a management philosophy based on the idea of maximizing efficiency without compromising productivity. Other companies have embraced lean and given it.

Die liefertreue eines mittelständischen unternehmens fertigung von elektronischen komponenten war nicht zufriedenstellend abläufe waren nicht eindeutig festgelegt dies führte zu unmut in der belegschaft da zahlreiche zusatztätigkeiten notwendig waren. Yet mobility is poised to make the most dramatic impact on the concept and use of lean. Western manufacturers began learning about lean in the early 1990s.

Wertstromanalyse im variantenreichen umfeld. How lean six sigma saved 4 million at ucsd medical center featuring lily angelocci. But one aspect of lean that has not been given enough attention in my opinion.

Lean manufacturing focuses on eliminating waste from the manufacturing process. Ohno was able to identify various activities in different work processes which can be removed. It is a passionate focus on serving customers.

Nonetheless there are significant differences as highlighted in.